Insulator Washing Systems Overview

AUTOMATED Advanced Live-Line Polluted Insulator Washing Systems

Eliminates Current Leakages and Flashovers in MV-HV-EHV POWER PLANT AND DISTRIBUTION SUBSTATION infrastructures.

Optimize Uptime, Maintain Reliable Power, Eliminate Cold Cleaning, and Wash Polluted Insulators While Energized.

Power Outage is not an option ›

HYBRID Advanced Live-Line Polluted Insulator Washing Systems

Eliminates Current Leakages and Flashovers in MV-HV-EHV POWER GRIDS AND GANTRY PARKS infrastructures.

Advanced Washing Systems for Glass, Ceramic, Polymeric, and RTV-Coated Insulators.

Cutting costs, not Maintenance ›

MOBILE Pumping Station & MOBILE Washers

For cleaning polluted Glass, Ceramic, Composite, and RTV-coated insulators in multiple locations.

We deliver worldwide and offer complimentary, customized case studies tailored to your specific infrastructure, cutting costs without compromising on Maintenance.

Global Reach, Tailored Solutions ›

POWER OUTAGE IS NOT A MAINTENANCE OPTION

Optimize Maintenance Budgets with Efficient GLASS, CERAMIC, POLYMERIC, AND RTV-COATED Insulator Cleaning.

Shorten or eliminate days or weeks of Power outage downtime, mitigating overall Leakage Currents, eliminating Flashovers, optimizing uptime and maintenance costs.

Optimize Maintenance Budgets with Efficient GLASS, CERAMIC, POLYMERIC, AND RTV-COATED Insulator Cleaning.

Shorten or eliminate days or weeks of Power outage downtime, mitigating overall Leakage Currents, eliminating Flashovers, optimizing uptime and maintenance costs.

ELIMINATE DAYS AND WEEKS OF MANDATORY OUTAGES: cut Material & Manpower Costs, RTV Coatings, Hand Cleaning and Greasing, reducing LOSS OF PRODUCTION and consequent LOSS OF REVENUES.

Global Reach, Tailored Solutions: we deliver worldwide and offer complimentary, customized case studies and budgetary quotes tailored to your specific infrastructure.

Leveraging over two decades of experience, we are the sole provider in the market certified to SN EN ISO 9001:2015 for the engineering and project management of Energized Insulator Cleaning Systems.

Wilorton Live Line's Advanced polluted insulator Washing technology is designed for critical power generation, transmission, and distribution (T&D) infrastructures operating in challenging climatic conditions.

It performs well in areas with high temperatures, humidity, dense fog, and limited natural cleaning due to short rainy seasons, followed by dry periods and foggy or misty conditions with light rain.

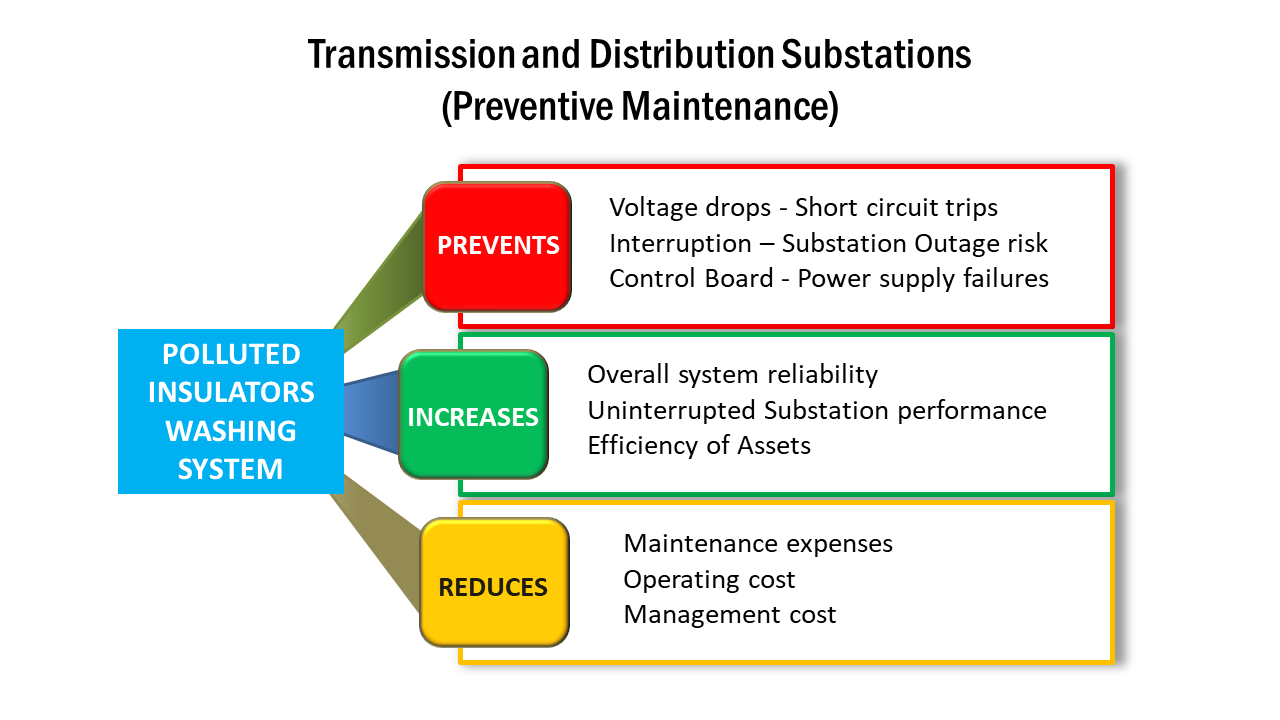

Preventive maintenance is the cornerstone of a reliable and efficient energy grid. Our advanced solutions address polluted insulators, a leading cause of power outages.

Eradicate Power Outages caused by pollution on POWER PLANT AND DISTRIBUTION SUBSTATIONS - POWER TRANSFORMERS – GANTRIES, and MV-HV-EHV TRANSMISSION & DISTRIBUTION POWER LINES (OHTL) with our Advanced Insulator Washing Systems.

AUTOMATED Advanced Live-Line Polluted Insulator Washing Systems

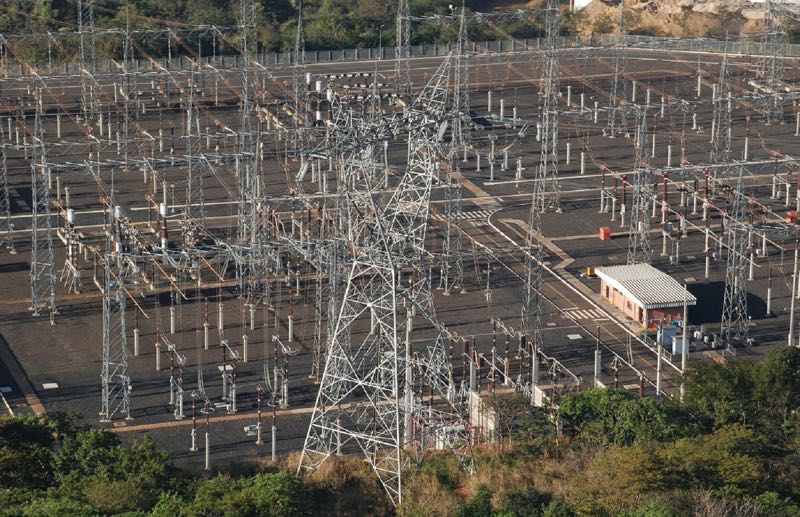

Eliminates Current Leakages and Flashovers in IN-SERVICE AND NEW POWER PLANT AND DISTRIBUTION SUBSTATIONS SWITCHYARDS, POWER TRANSFORMER BAYS .

Wilorton Live Line's Automated, Advanced polluted insulator Washing technology is designed for critical power generation, transmission, and distribution (T&D) infrastructures operating in challenging climatic conditions.

It performs well in areas with high temperatures, humidity, dense fog, and limited natural cleaning due to short rainy seasons, followed by dry periods and foggy or misty conditions with light rain.

Eliminates Current Leakages and Flashovers caused by pollution in MV-HV-EHV POWER PLANT and DISTRIBUTION SUBSTATIONS, POWER TRANSFORMER’S BAYS, and GANTRY’s parks Infrastructures.

Mantain uninterrupted Power

POWER OUTAGE IS NOT A MAINTENANCE OPTION

The Wilorton Automated Advanced & Washing System (AWS) is a game-changer. It effectively eliminates flashover incidents caused by polluted insulators on energized lines, significantly reducing network outages. This means you can rely on a more stable power supply without the need for downtime associated with repair and traditional cleaning methods. The AWS system is your key to operational excellence and optimized maintenance budgets through efficient resource allocation.

Our Energized Insulators Washing Systems ensure network reliability by cleaning the insulators' pollutants buildup on any glass, ceramic, composite and polymeric, and RTV coated insulators.

Global Reach, Tailored Solutions. We understand that every infrastructure is unique. That's why we deliver our solutions worldwide and offer complimentary, customized case studies and budgetary quotes tailored to your infrastructure.

With us, you're not just a customer; you're a partner in ensuring uninterrupted power.

AUTOMATED WASHING SYSTEM SCOPE:

Eliminate days or weeks of planned or unplanned maintenance outages for insulators' cleaning, de-energizing the substation equipment, workforce mobilization, and repair costs. Thus, eliminating losses of power production, revenues, and turnover, improving overall CAIDI-CAIFI-SAIDI-SAIFI Indexes.

AUTOMATED WASHING SYSTEM (AWS) OUTLINE:

AWS equipment: Pumping station with high-pressure electric pump, demineralized water storage tank, water distribution pipeline, electro-mechanical controls, including anemometer to check the wind direction and speed, and a control panel.

The AWS control system checks pre-defined parameters such as the water storage level, water resistivity/conductivity, wind speed and direction, and electromechanical system efficiency.

The AWS parameters are user-programmable.

The pollutant type and build-up rate dictate the water pressure, washing time, and frequency. Water pressure and washing time parameters are determined during the AWS design, test, and commissioning. Demineralized water with minimum permissible conductivity is required.

Cleaning Frequency may vary depending on the degree of contamination, the weather conditions, and the insulator design. The automatic washing cycles are user-programmable.

Automated washing system COST & PERFORMANCE ONLINE CALCULATOR for Utilities

If you are an Utility Company, register to gain access to our online calculator useful to frame a preventive maintenance program with relevant details, such as washing efficiency and investment cost in installing an Automated Washing System on your most critical infrastructure affected by pollution.

Note: Calculations simulated are estimated, please contact us for a free of charge case/cost study for your infrastructure.

Visit Wilorton Youtube Channel to watch more polluted energized insulator live washing videos.

For news and updates, please follow our dedicated showcase page on LinkedIn

AUTOMATED WASHING SYSTEM Case/Cost studies:

› 400 kV Power Plant Substation

› 220-33-11 kV Distribution Substation

AUTOMATED WASHING SYSTEM Sample applications:

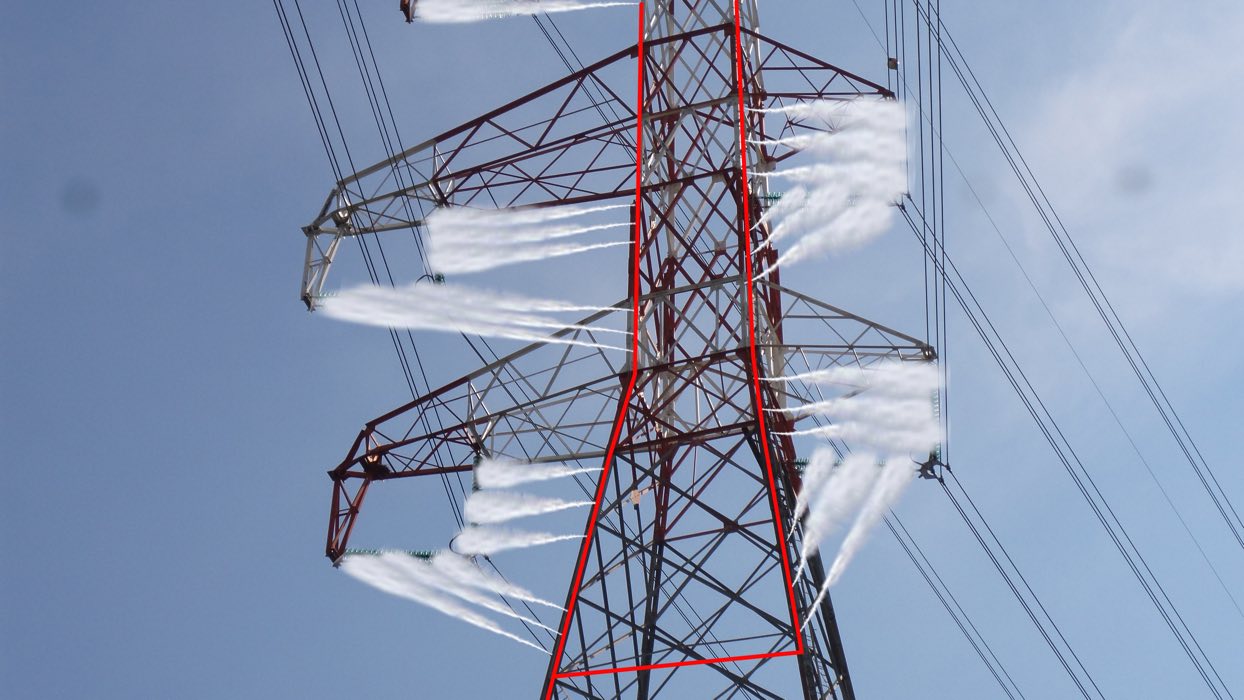

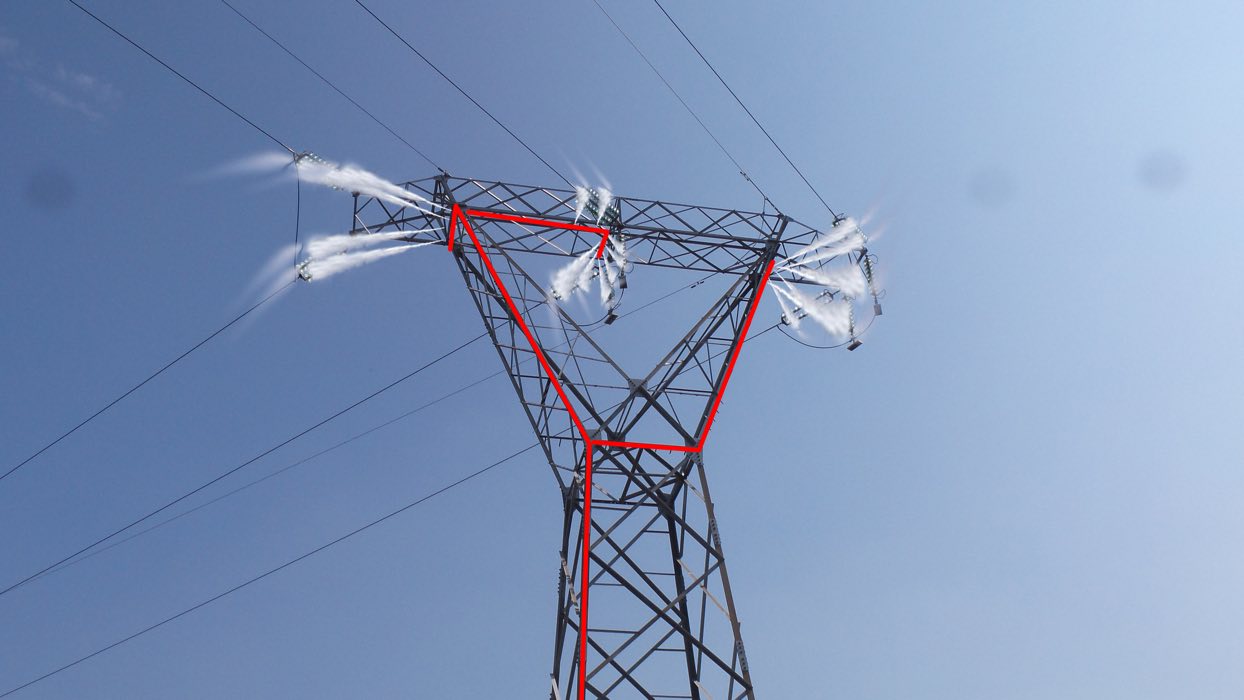

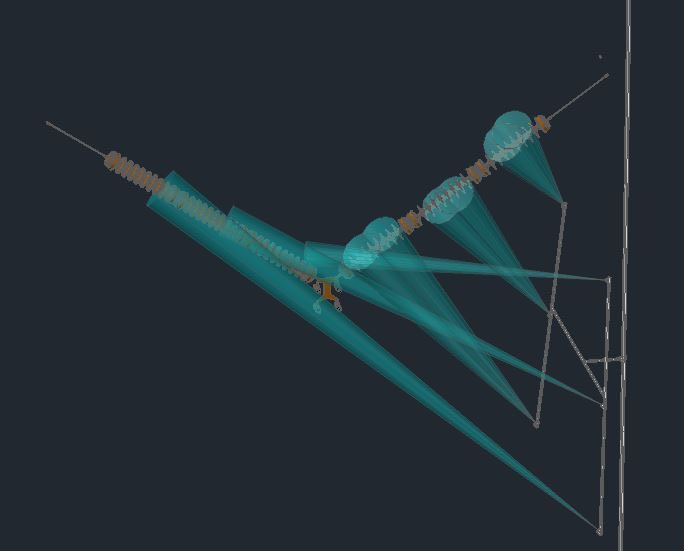

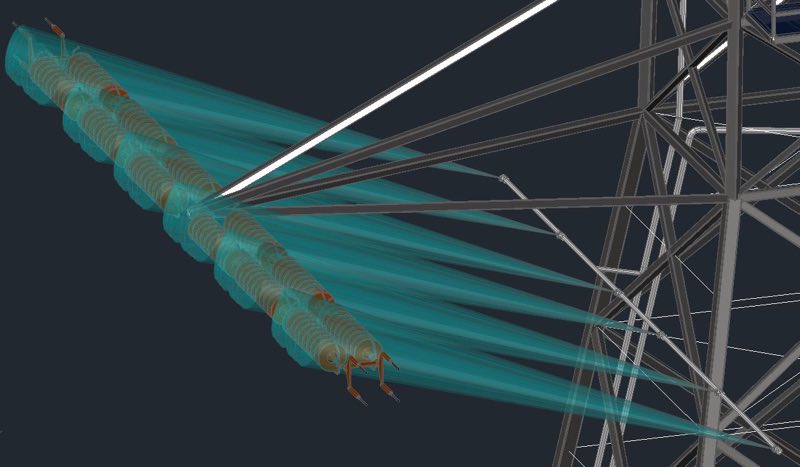

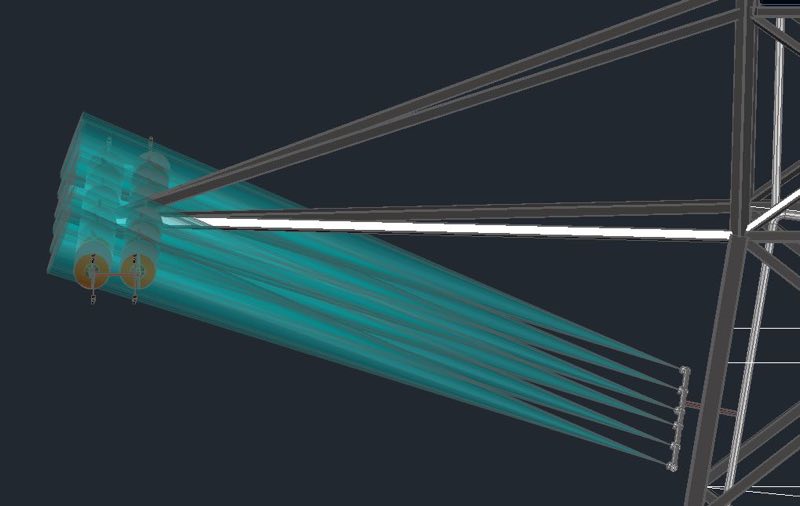

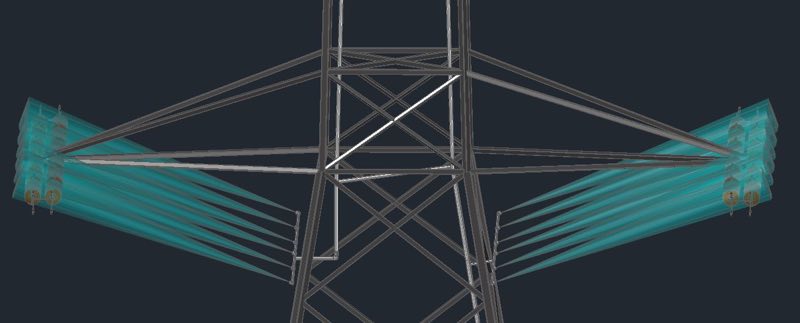

HYBRID Advanced Live-Line Polluted Insulator Washing Systems

Eliminates Current Leakages and Flashovers in MV-HV-EHV POWER GRIDS AND GANTRY PARKS INFRASTRUCTURES.

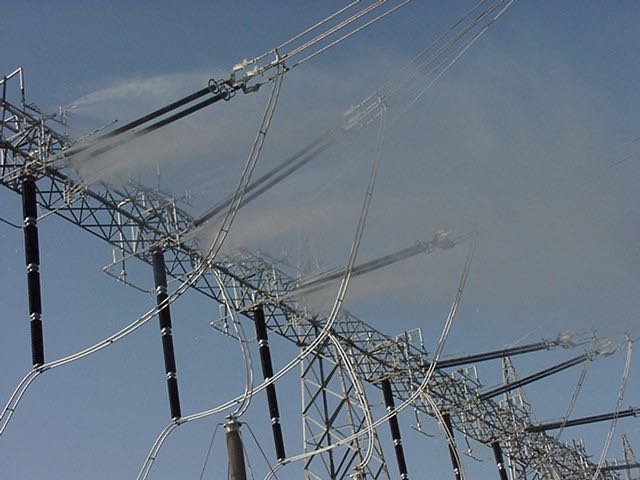

Clean insulators without a power outage.

Wilorton Hybrid Advanced Washing System grants zero flashovers (caused by polluted insulators), reducing network outages, eliminating repair time and maintenance costs, attains operational excellence, reduces downtime risk, ensures personnel safety, and achieves financial efficiency by optimizing the maintenance budget.

Our Energized Insulators Washing Systems ensure network reliability by washing away the insulators' pollutants buildup on any glass, ceramic, composite and polymeric, and RTV coated insulators.

Installing a HYBRID WASHING SYSTEM reduces overall CAIDI-CAIFI-SAIDI-SAIFI Indexes.

Customer Average Interruption Duration Index (CAIDI) indicates the average time required to restore service during a predefined period.

The electric distribution System's Average Interruption Duration Index (SAIDI): Indicates the length of time all customers would have been out of power if the total number of hours out of service in a year were to be shared. It is typically measured in minutes.

Customer Average Interruption Frequency Index (CAIFI): Measures the average number of interruptions per customer interrupted per year. It is simply the number of interruptions that occurred divided by the number of customers affected by the interruptions.

The System Average Interruption Frequency Index (SAIFI) is the average number of service interruptions experienced by a customer in a year. The index is computed based on the methodology in the DB16-20 studies.

HYBRID WASHING SYSTEM SCOPE:

Eliminating maintenance outages for insulators' cleaning (De-energizing the equipment), repair costs, and improving the income statement from the loss of turnover, preventing power outages caused by polluted insulators.

HYBRID WASHING SYSTEM OUTLINE:

HYBRID washing system requires the installation of water rigid piping with stainless steel quick coupler installed in a coupling box at the structure base, connecting to the mobile washer high-pressure flexible hose.

Simultaneous wash of energized insulators mounted on a Tower-Tubular pole or Gantry in 15/25/60 seconds depending on the tower configuration. The water envelopes and swamps all energized insulators in one surge.

Washing effectiveness is limited by wind speed. High washing rates are achieved with calm or low-speed wind conditions.

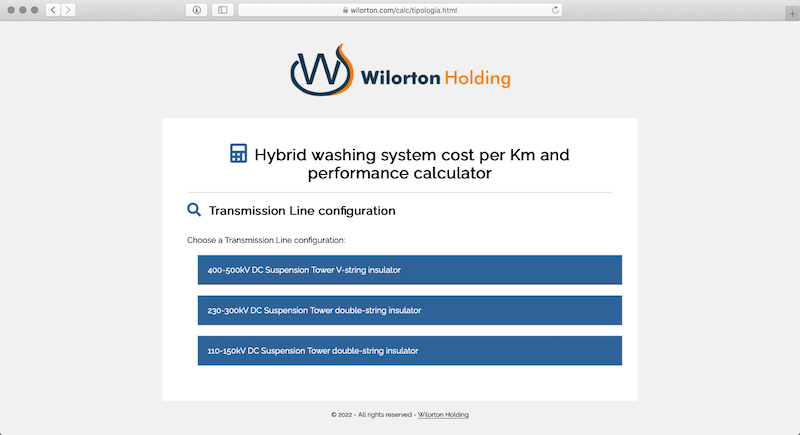

Hybrid washing system COST PER KM & WASHING PERFORMANCE online calculator for Utilities

If you are an Utility Company, register to gain access to our online calculator useful to frame a preventive maintenance program with relevant details, such as washing efficiency and investment cost in installing an Hybrid Washing System on your most critical infrastructure affected by pollution.

Note: Calculations simulated are estimated, please contact us for a free of charge case/cost study for your infrastructure.

Watch a short video introducing our advanced Online Calculator useful to frame a preventive maintenance program WITHOUT POWER OUTAGE, reducing power lines downtime (CAIDI-SAIDI-CAIFI-SAIFI Indexes).

Click here to try it now ›

Visit Wilorton Youtube Channel to watch more polluted energized insulator live washing videos.

For news and updates, please follow our dedicated showcase page on LinkedIn

HYBRID WASHING SYSTEM Case/Cost studies:

› 150 kV Distribution Substation

› 500 kV Transmission Power Line

HYBRID WASHING SYSTEM Sample applications:

MOBILE Pumping Station & MOBILE Washers

For cleaning polluted Glass, Ceramic, Composite, and RTV-coated insulators in multiple locations.

Clean insulators without a power outage.

Wilorton Mobile Washing System grants zero flashovers (caused by polluted insulators), reducing network outages, eliminating repair time and maintenance costs, attains operational excellence, reduces downtime risk, ensures personnel safety, and achieves financial efficiency by optimizing the maintenance budget.

Our Energized Insulators Washing Systems ensure network reliability by washing away the insulators' pollutants buildup on any glass, ceramic, composite and polymeric, and RTV coated insulators.

Visit Wilorton Youtube Channel to watch more polluted energized insulator live washing videos.

For news and updates, please follow our dedicated showcase page on LinkedIn

MOBILE WASHING SYSTEM SCOPE:

Eliminating maintenance outages for insulators' cleaning (De-energizing the equipment), repair costs, and improving the income statement from the loss of turnover, preventing power outages caused by polluted insulators.

MOBILE WASHING SYSTEM OUTLINE:

Mobile Insulator washing equipment consists of a completely integrated system mounted on a steel frame carried by a suitable trailer/chassis, to wash energized insulators from the ground, from an aerial device, or through a piping system pre-installed on the power lines and gantries.

Our mobile insulator washing Unit, MK Series, can be mounted on:

› Skid (frame), MK-S Series

› Chassis, MK-C Series

› Flatbed-Trailer, MK-T Series

MOBILE WASHING SYSTEM Case/Cost studies:

› 11-33-34.5 kV Transmission Power Line

› 500 kV Transmission Power Line

MOBILE WASHING SYSTEM Sample applications:

Download our 'POWER OUTAGE IS NOT A MAINTENANCE OPTION' White Paper

Download our 'POWER OUTAGE IS NOT A MAINTENANCE OPTION' White Paper

Follow our Social Channels

Videos, tech articles, case/cost studies and more: